In the fiercely competitive domain of safety workwear manufacturing, Tomax has gained certain recognition in the industry for its outstanding advantages in design, research, development and quality control. Our laboratory, which plays a key role in driving innovation and maintaining the highest quality standards. Before we delve into the overall function of the laboratory in the R&D and production process, let’s first take a look at what testing instruments we have.

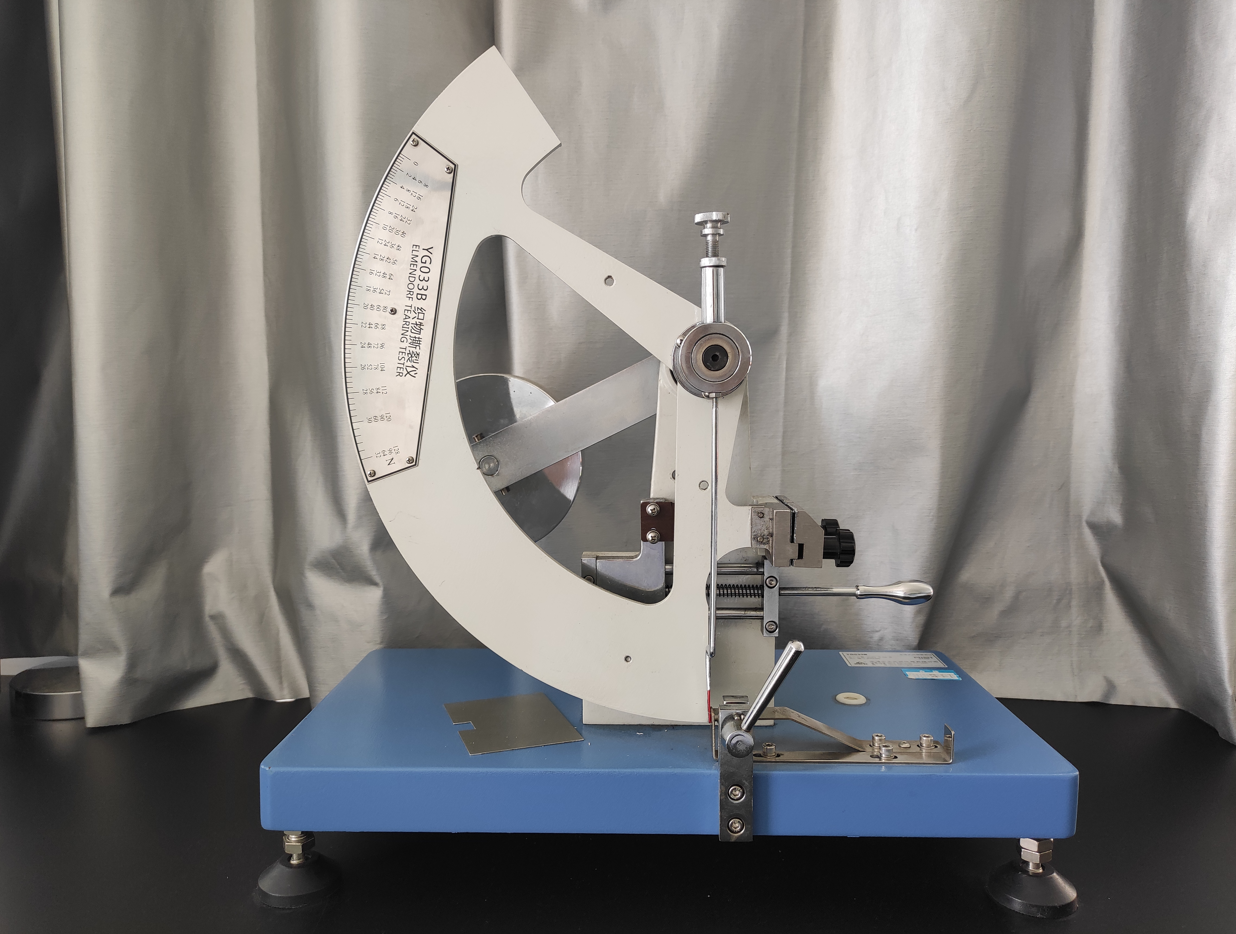

Tear and Tensile Strength Testers

The BTTG-equivalent tear and tensile strength tester are the cornerstones of fabric durability assessment—especially critical when evaluating fabrics that have undergone multiple functional treatments. In the R&D process, when fabrics are subjected to processes like waterproof coating, flame retardant finishing, or anti-static treatments, there's a risk that their inherent strength could be compromised. These testers simulate extreme stress conditions to ensure that even after comprehensive functional processing, the fabric's tear resistance remains uncompromised.

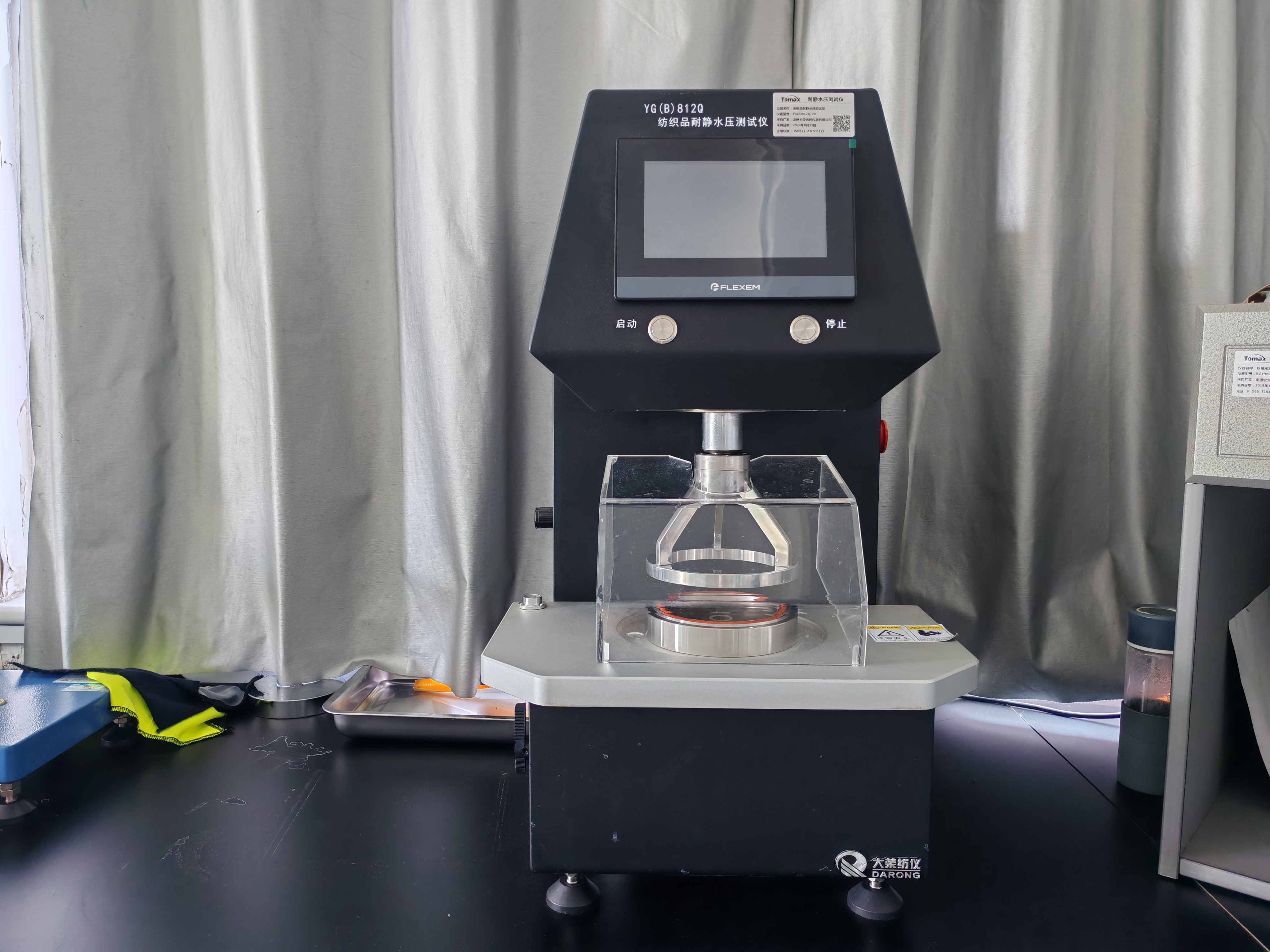

Hydrostatic Pressure Tester

For workwear designed for high-stakes wet environments, the hydrostatic pressure tester plays a non-negotiable role. Specifically tailored to industries like offshore operations, oil & gas, and mining—where workers face prolonged exposure to water and moisture with other dangerous factors—the tester rigorously evaluates a fabric's waterproofing capability. By simulating the hydrostatic pressure encountered in offshore rigs, oil field downpours, or mine shaft conditions, it ensures that fabrics can maintain a reliable barrier against water ingress. This precision testing guarantees that protective gear for these industries keeps wearers dry and safe.

D65 Light Source Box

Central to maintaining brand consistency and customer trust, the D65 light source box serves as the guardian of color uniformity across production batches. In workwear manufacturing, color inconsistencies can lead to safety hazards (e.g., compromised visibility in high-visibility gear) or brand reputation issues. This instrument creates a standardized lighting environment that mimics natural daylight, allowing our team to meticulously compare color samples across different production runs. By subjecting each batch to rigorous color matching against the original design specifications, we minimizes variances that might arise from dye lot differences, manufacturing tolerances, or environmental factors.

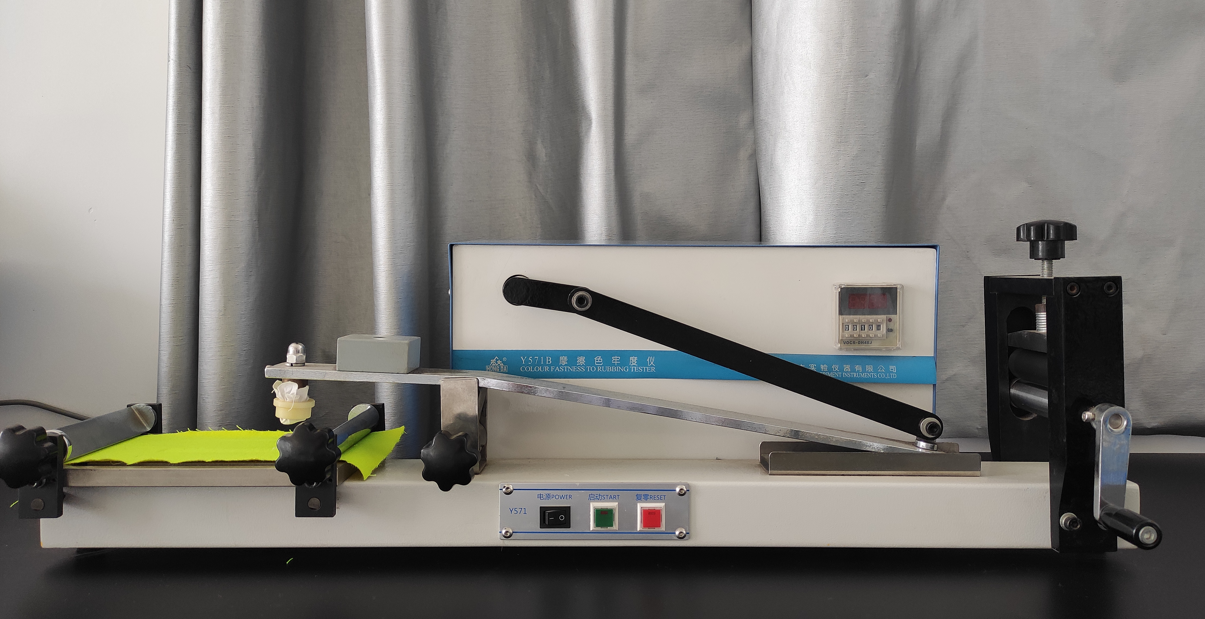

Colorfastness Testers

The dry and wet crocking colorfastness testers, along with the perspiration colorfastness tester, simulate real - world situations that workwear encounters, such as rubbing, sweating, and normal wear. These tests are crucial for maintaining the visual appeal and brand identity. By ensuring that the colors of workwear remain vibrant over time, we enhance both the aesthetic value and the longevity of the garments.

Flame Retardancy Tester

In high - risk industries like oil and gas and electrical work, fire safety is of utmost importance. The fabric flame retardancy tester subjects our fabrics to strict fire - resistance tests. Only fabrics that pass these stringent evaluations are used in workwear for such environments, providing reliable protection and safeguarding the lives of the wearers.

Washing and Drying Equipment

Our laboratory is equipped with a comprehensive range of washing and drying machines, including those for colorfastness testing according to European and American standards, as well as fabric functional resistance-to-washing testing machines. These machines replicate various real - world washing and drying cycles, allowing us to assess how fabric performance, color, and functionality hold up over multiple laundering processes. This ensures that our workwear remains durable, comfortable, and functional throughout its lifespan.

The Laboratory's Role in R&D and Production

Armed with this sophisticated array of testing instruments, Tomax's laboratory serves as the nerve center of our safety workwear production. In the research and development phase, the laboratory is where innovative fabric technologies come to life. By subjecting potential fabrics to a battery of tests, we can identify and develop materials that meet the specific needs of different work environments, from extreme weather conditions to high-risk industrial settings.

During the production process, the laboratory acts as an unwavering sentinel, ensuring that every piece of workwear adheres to our exacting quality standards. From the initial material selection, where raw materials are tested against international benchmarks like ISO and ASTM, to in-line quality monitoring. After each treatment, such as dyeing, coating, and functional finishing, the relevant testing instruments swing into action to verify compliance with international standards.